Graphic Overlay and Panels-- Accuracy Engineering for Control Panels and Displays

Graphic Overlay and Panels-- Accuracy Engineering for Control Panels and Displays

Blog Article

Trick Variables to Think About When Designing Graphic Overlays and Panels

In the realm of visuals overlays and panels, several essential elements call for careful factor to consider to ensure ideal capability and durability. In addition, one must account for ecological problems that can impact the overlay's stability and conformity with regulatory requirements.

Product Selection

When it involves visuals overlays and panels, material choice plays a crucial role in figuring out both capability and aesthetics. The option of products significantly influences the toughness, look, and performance of the overlays, ultimately affecting customer experience and item longevity.

Usual products consist of polycarbonate, plastic, and polyester, each offering distinctive benefits. Polycarbonate, for circumstances, is understood for its high effect resistance and clarity, making it suitable for high-traffic environments where resilience is important.

Additionally, the thickness and appearance of the product can improve tactile feedback and aesthetic allure, more adding to individual interaction. Factors such as UV security, temperature level resistance, and adhesive compatibility are also essential factors to consider throughout material option. Inevitably, the appropriate material not only straightens with the layout goals but additionally makes certain that the graphic overlays and panels efficiently serve their desired objective, preserving both functionality and aesthetic honesty with time.

Interface Style

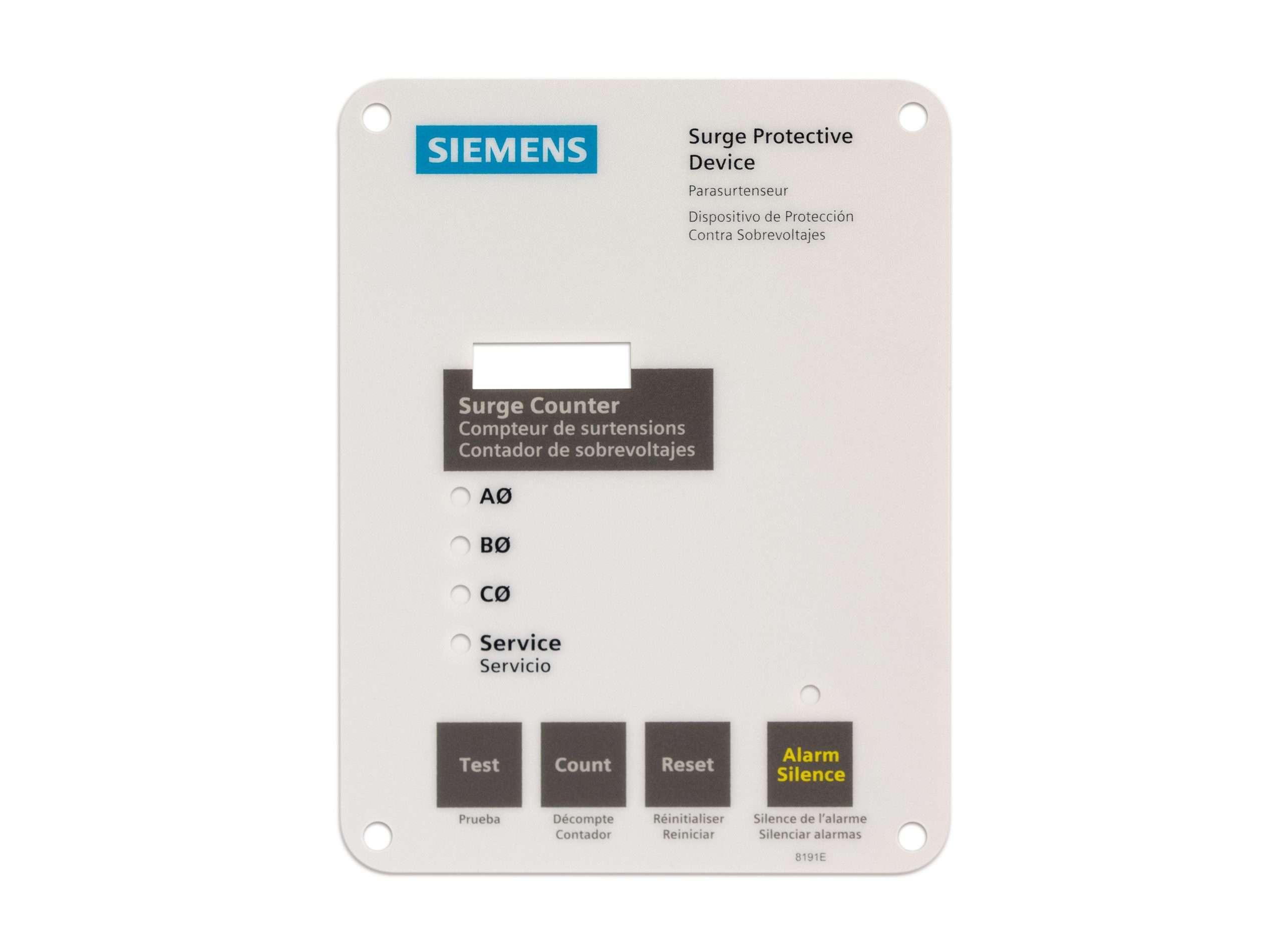

Efficient interface layout is necessary for enhancing customer experience and making sure intuitive communication with graphic overlays and panels. A properly designed interface not only facilitates user engagement however additionally lowers the discovering contour related to brand-new innovations. This is specifically essential in settings where quick decision-making is essential, such as medical tools or industrial control systems.

To accomplish reliable interface style, clarity is critical. Symbols, buttons, and other aesthetic components should be quickly recognizable and convey their functions without obscurity. Using constant shade systems, typography, and layout produces a natural experience that overviews customers through interactions efficiently.

Moreover, the placement of controls need to be instinctive, allowing individuals to browse the user interface naturally. This involves thinking about the individual's operations and designing overlays that reduce unnecessary activities. Responses devices, such as auditory or visual signals, can likewise improve use by validating customer actions and offering assistance.

Durability and Longevity

Resilience and long life are important consider the design of visuals overlays and panels, particularly sought after settings where tools undergoes tear and put on. Designers have to prioritize products and building techniques that can withstand physical, mechanical, and chemical stress and anxieties over time.

The option of products plays a considerable role in guaranteeing sturdiness. Using polycarbonate or polyester movies can boost resistance to scrapes, impacts, and fading. Additionally, including UV-resistant finishes can assist maintain look and capability under extended exposure to sunshine.

Adhesive option is similarly essential, as it must give solid bonding while allowing for thermal development and contraction. A top notch adhesive will prevent delamination and make certain that the overlay stays securely affixed under various problems.

Ecological Conditions

Ecological conditions play a significant look here function in the performance and long life of graphic overlays and panels. Variables such as temperature, moisture, UV exposure, and chemical exposure has to be thoroughly considered throughout the layout process. High temperature levels can result in distortion or bending, while extreme cold might result in brittleness, impacting the overlay's honesty.

Humidity can trigger adhesion problems, possibly resulting in delamination or bubbling, which endangers the useful and visual elements of the panel. UV direct exposure is an additional vital factor to consider; prolonged sunlight can trigger fading and destruction of the graphics, necessitating the usage of UV-resistant products or coverings to preserve visual allure and legibility in time.

In addition, environments that subject overlays to extreme chemicals, such as cleaning agents or industrial compounds, can cause product destruction. Selecting substrates and inks that are resistant to such chemicals is crucial to ensure resilience.

Ultimately, understanding the particular environmental conditions in which the graphic overlays and panels will operate allows developers to pick ideal products and style methods, hence improving both performance and durability. (Graphic Overlay and Panels)

Governing Conformity

How can producers guarantee that their graphic overlays and discover this panels meet necessary governing criteria? Conformity with market policies is vital for producers to maintain safety and capability in their items. To accomplish this, manufacturers should initially determine the appropriate standards that put on their certain applications. Overlays made use of in medical devices might need to abide with FDA guidelines, while those for automobile applications must stick to ISO standards.

In addition, carrying out regular testing of products and prototypes against developed requirements is vital. By integrating these practices, producers browse around this site can guarantee their visuals overlays and panels not only fulfill regulative demands but additionally improve product integrity and customer count on.

Conclusion

In verdict, the design of graphic overlays and panels demands mindful consideration of several important factors. By dealing with these aspects, developers can develop enduring and effective graphic overlays and panels that satisfy varied demands.

In the world of graphic overlays and panels, a number of essential variables warrant careful consideration to guarantee ideal performance and durability. Eventually, the ideal product not just straightens with the layout objectives yet additionally makes certain that the visuals overlays and panels properly offer their desired objective, keeping both capability and visual stability over time.

Efficient individual interface style is essential for enhancing customer experience and ensuring instinctive communication with visuals overlays and panels. By integrating these practices, manufacturers can ensure their visuals overlays and panels not just meet regulative requirements yet likewise improve product dependability and consumer trust.

In verdict, the layout of graphic overlays and panels necessitates careful factor to consider of a number of important elements.

Report this page